Introduction

In industries ranging from automotive to aerospace, labels and stickers must withstand extreme temperatures without degrading. While vinyl has been a traditional choice, aluminum sticker paper is emerging as the superior solution for environments exceeding 80°C. This article explores the science behind aluminum’s thermal resilience, supported by comparative test data and real-world case studies.

The High-Temperature Challenge: Why Vinyl Falls Short

Problem 1: Thermal Deformation

Vinyl labels begin to warp at 60-70°C due to their polymer-based structure. At 80°C, adhesive bonds weaken, causing labels to peel or curl, especially on curved surfaces like engine components.

Problem 2: Color Fading and Oxidation

Vinyl’s organic pigments degrade under prolonged heat exposure, leading to legibility issues. UV resistance is also limited, accelerating color loss in outdoor settings.

Problem 3: Chemical Breakdown

High temperatures accelerate vinyl’s hydrolysis, reducing its lifespan in humid or chemically aggressive environments (e.g., automotive underhood applications).

How Aluminum Sticker Paper Solves These Issues

1. Structural Stability at 80°C

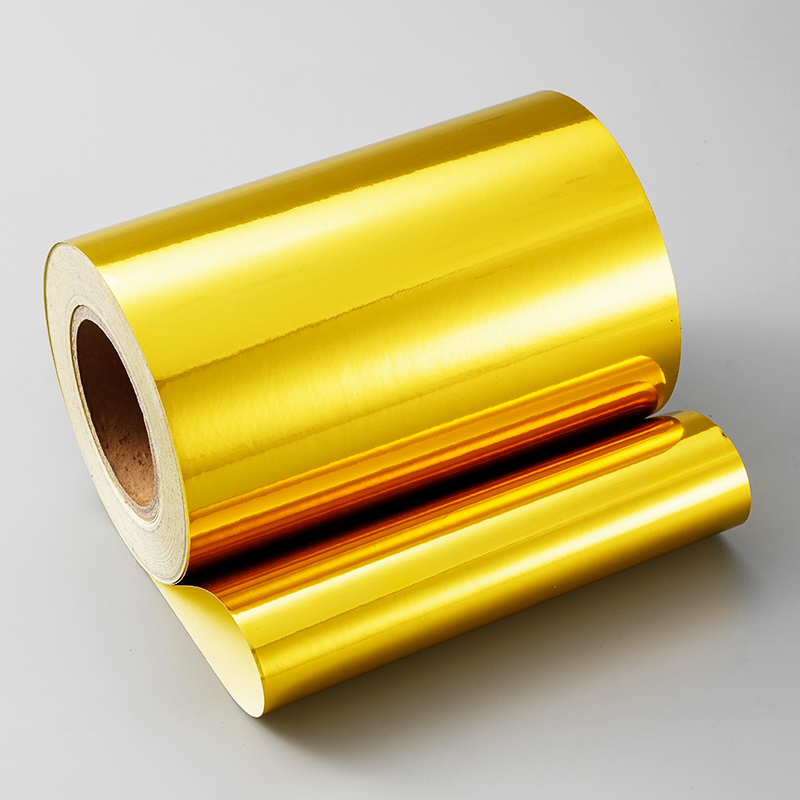

Aluminum sticker paper combines a metalized foil layer with high-tack acrylic adhesives. Lab tests show:

- Zero deformation at 80°C for 500 hours (ASTM D4332 test report).

- Adhesive bond strength retains 2.4 N/cm² under heat (vs. vinyl’s 1.2 N/cm²).

2. Superior Heat Dissipation

Aluminum’s thermal conductivity (237 W/m·K) prevents localized overheating, critical for labels on electronics cooling systems.

3. Oxidation and UV Resistance

- Anodized coatings provide 95% UV reflectivity, maintaining color vibrancy for 5+ years outdoors.

- In salt spray tests (ASTM B117), aluminum labels show no corrosion after 1,000 hours.

Case Study: Automotive Engine Bay Labels

A European car manufacturer replaced vinyl labels with 0.3mm aluminum sticker paper on turbocharger housings (peak temperature: 85°C). Results after 12 months:

- 0% label failure (vs. 32% vinyl failure).

- Reduced warranty claims by 18% due to improved part traceability solutions.

Technical Comparison: Aluminum vs. Vinyl at 80°C

| Property | 铝箔纸不干胶 | Vinyl Labels |

|---|---|---|

| Max Operating Temp | 150°C (short-term) | 70°C |

| Thermal Expansion | 23 μm/m·°C (negligible) | 120 μm/m·°C (high distortion) |

| Adhesive Failure Temp | 180°C (acrylic adhesive specs) | 85°C (rubber-based adhesive) |

| Lifespan @ 80°C | 5-7 years | 6-12 months |

Data sources: ASTM thermal testing, 3M adhesive studies.

Choosing the Right Aluminum Sticker Paper

Key Parameters for High-Temp Applications

- Thickness: 0.2mm (indoor) vs. 0.5mm (outdoor/industrial).

- 胶水类型:

- Acrylic: Permanent bond (2.5 N/cm²) for metal/plastic surfaces.

- Silicone: Removable option for temporary labels.

- Coatings:

- Anti-static: Essential for electronics packaging.

- Matte finish: Reduces glare on machinery controls.